Within this system fabric rolls are graded for defects. Allocate a trained quality inspector for visual inspection.

Fabric Inspection Systems For Apparel Industry Garments Fashion Retail Features The Itj

Become aware of safety hazards and responsibilities 4.

How to doing fabric inspection. This will minimize the quantity of panels or garments rejected for fabric faults thereby. For a rub test bring a white cotton cloth. All of these are traditionally carried by the inspector.

First it is not enough in itself. In simple words their decision will. Make sure the fabric is not upside down.

Price quality and service are three primary elements that are carefully monitored at the Apparel Search Company. Return fabrics to the supplier that doesnt meet agreed-upon quality standards. If your company is equally concerned about quality assurance you should educate yourself about Testing Methods Human Rights factory inspections etc.

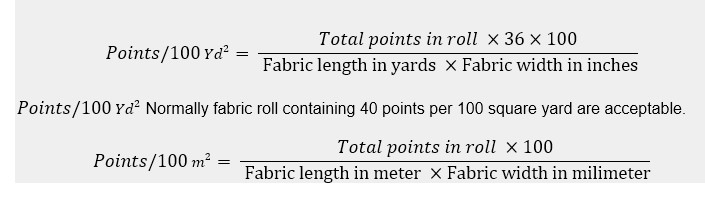

The most commonly used is the Four point system. What kind of equipment is needed to carry out the inspection. Prepare inspection forms and inspection plan 5.

The inspector can really check every detail including counting the total quantity and confirming the packaging. A maximum skewing of 2 cm for the chest of 60 cm is acceptable but not more. Some OIGs make a distinction between inspection and evaluation work.

The very least is to bring a garment measurement tape as well as a digital camera. Beyond these simpler checks two industry methods used are the Ten point and Four point systems. The client will select the appropriate fault rate and standard to determine the acceptance of each shipment.

Fabric upside down. A full function check to make sure that a DVD player really works. Compare actual fabric width and length against reported figures by supplier and required length and width.

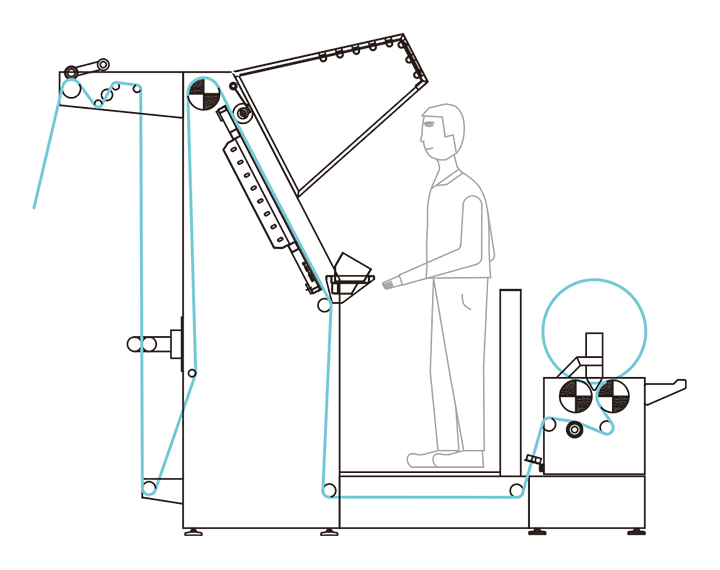

Fabric Inspection Guidelines. In fabric inspection fabric rolls are opened and passed through a fabric checking machine having the light under the fabric and the fabric checker does the visual inspection of the fabric. An inspection criteria sheet ICS or simply a QC checklist outlines quality requirements and specifications with your products in a way that makes them clear concise and user friendly for your supplier.

The inspection and evaluation function at each DepartmentAgency is tailored to its unique mission. The idea is to identify contain and resolve issues as quickly as possible. Method for QC on Fabric.

Inspecting the goods after they are made and packed is the standard QC solution of most importers. Inspection of equipment 8. One of the main benefits of third party inspections as opposed to those performed by either the manufacturer or the buyer is that the inspectors performing TPIs are unbiased by either side and can thus deliver a verdict that is fair without compromising the interests of either party while of course looking out for the client and the requirements put forward.

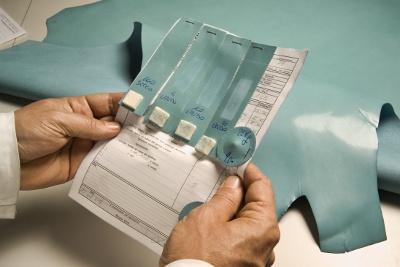

Inspection of jobsite conditions 6. Inspection of materials 7. While checking fabric checker marks the defects with a chalk or put a sticker on the defects.

It is quite common to check the main fabrics weight. Some simple tests can be done by the inspector in the factory instead of sending samples to a laboratory. Thus to be responsive to the needs of the Inspector General community it is important that the standards for.

Fabric inspection focuses on faultdefect rate color end to end and edge to middle shading handhandle and appearance. Attend the pre-job conference 3. Inspections can be conducted at any point throughout the production process with the maximum benefit observed when strategically employed at the beginning first-article in-process 30 -50 complete and pre-shipment 100 produced and at least 80 packaged.

Its one of the simplest yet most effective ways to. To avoid creating delays inspectors can usually start after all products are finished and. A factory might identify some problems hide them away from the inspector and then ship them out.

If labels include barcodes bring a barcode scanner. What are the limits of inspection during production. Preliminary Inspection Responsibilities 1.

Final inspections are usually performed in a hurry just before shipment. Read and understand the job specification 2. This defect can be solved by re-setting of the fabric at the fabric mill.

Fabric Inspection Machine For Fabric Mill Auto Garment

Fabric Inspection Four Point System Textile Study Center

Bulk Review Meeting In 2021 Inspect Process Control System

How To Make Garment Inspection Report Simple Method And Advanced Method Report Template Templates Inspection Checklist

Fabric Inspection Systems For Apparel Industry Garments Fashion Retail Features The Itj

Sop Of Fabric Inspection Knitting Clothing

Suntech Fabric Inspection Machine

Fabric Inspection Four Point System Textile Study Center

Fabric Inspection In Apparel Manufacturing Textile School

Sop Of Fabric Inspection Knitting Clothing

Fabric Inspection Machine For Fabric Mill Auto Garment

Garment Inspection Should Be Done In Clockwise Direction As Shown Below

5 Essential Garment Inspection Steps To Protect Your Quality

Suntech Fabric Inspection Machine

Fabric Inspection Systems For Apparel Industry Garments Fashion Retail Features The Itj

How To Use 4 Point System For Knits Fabric Inspection

How To Eliminate Fabric Inspection From Garment Manufacturing Process

Fabric Inspection Systems For Apparel Industry Garments Fashion Retail Features The Itj

Sop Of Fabric Inspection Knitting Clothing